Power plants consumed 530 million tonnes of coal in 2014-15, which is around three-fourths of the total coal use in the country

In a study which spanned over two years beginning early 2012, non-profit CSE assessed the environmental performance of coal-based power sector—one of the most critical sectors of the Indian economy. The findings, released in February 2015, revealed a grim picture. Coal-fired power sector was found to be one of the most resource wasteful and polluting sectors in the world. Our pollution norms are significantly weaker than other major economies, including China, where the particulate matter (PM) norms are 30mg/Nm3 compared to India’s range of 150-350 mg/Nm3.

What is more worrying is that two-thirds of the power plants failed to comply with even these lenient standards, the study found. One of the reasons could be that the plants could afford to ignore regulatory penalties since electricity is an essential service and shutting down even flagrantly violating plants was not an option.

Power plants consumed 530 million tonnes of coal in 2014-15, which is around threefourths of the total coal used in the country. India’s coal is of poor quality with almost 40 per cent ash, which means the plants burn 0.74 Kg/KWh of power generation, which is 41 percent higher than the global average. Poor coal also means more pollution. As a result, coal- based power plants are a significant contributor to total pollutants such as PM, NOX and SO2 in the country (see ‘Contribution of coal-based power sector to industrial emissions’).

Domestic power plants were also found to be inefficient in using fresh water. Their average fresh water consumption is around twice that of the US and Chinese plants. Thermal power sector cumulatively withdraws around 22 billion cubic metres (BCM) annually, a significant usage considering that the country’s total domestic needs are estimated at 43 BCM.

Given the pace of growth of coal-based power generation (capacity is expected to reach 260 GW by 2022, up from 170 GW as of September 2015), pollution will worsen if emission regulations are left unchanged. Based on its findings and study of best practices in the sector globally, CSE suggested several policies and regulations—ranging from tighter air pollution standards and efficient technology to developing policy framework for managing waste products—to improve the sector.

The results of CSE’s study and its recommendations spurred a wide public debate and, over the last few months, the government announced a series of draft regulations and policies to help improve the sector’s performance.

New Developments

Air pollution standards: In December, 2015, the Ministry of Environment, Forests and Climate Change announced new regulations on air pollution standards that are in line with emission norms of leading economies such as the USA, the EU and China. While the existing standards governed only PM emissions, the new regulations will impose stringent standards for all major pollutants—PM, SO2, NOx and mercury emissions.

Under these regulations, plants installed in and after 2017 would need to meet PM emission standards of 30 mg/Nm3—an 80 per cent reduction over the current norms. New plants would also need to install pollution-control equipment such as Flue Gas Desulphurization and low NOx burners to meet the standards. Older plants would need to meet looser standards, based on their age, due to both economic considerations and technical challenge (see ‘Comparison of proposed norms in India with other key countries’ p96).

Water use: The new norms can have a remarkable reduction in freshwater withdrawal by thermal power plants—cumulative freshwater withdrawal could decrease by 80 per cent from around 22 BCM in 2011-12 to around 4.5 BCM in 2016-17. The norms will require all freshwaterbased once-through-cooling (OTC) system plants to install water-efficient cooling towers that consume up to four cubic metre per watt hour (m3/MWh). Furthermore, existing cooling tower-based plants will need to restrict water consumption to 3.5 m3/MWh and plants that will be set up after January 2017 have to achieve 2.5 m3/MWh.

Fly ash: Since the utilisation of fly ash from power plants has been far below the 100 per cent target that was supposed to be achieved by 2014, the government introduced draft amendments in March 2015 to push fly ash use. The proposed notification mandates construction activities (buildings, roads and flyovers, reclamation and embankments) within 500 km of power plants to use only fly ash. It also requires power plants to provide fly ash for free to construction agencies and to transport it at their own cost up to 100 km for private users and up to 500 km for government projects.

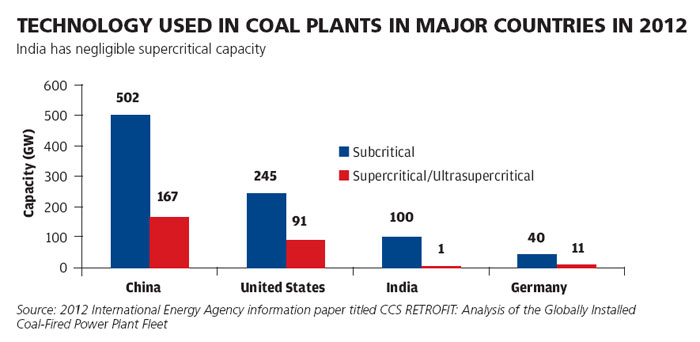

Supercritical technology: The Ministry of Power announced its plans to mandate supercritical technology for Ultra Mega Power Projects (UMPPS) as well power projects during the 13th Five Year Plan period, however, almost 40 GW of the 87 GW capacity under construction is subcritical. The power ministry has also announced plans to shut down around 36 GW of old capacity that is inefficient.

Key challenges ahead

The strange case of power deficits and idle power plants: Electricity is central to India’s developmental efforts, yet a quarter of our population lives without access to it. Our per capita consumption of electricity is also considerably low, at almost a third of the world average with millions getting power a few hours a day. Surprisingly, the plant load factor (PLF) for power plants has steadily declined over the last two years and was only 63.60 per cent in September 2015. PLF is the ratio between the actual energy generated by the plant to the maximum possible energy that can be generated with the plant working at its rated power capacity for a given duration.

The reason behind the low PLF could be that there has been a sharper increase in total capacity as compared to the growth in demand. Coal shortages and grid problems are also responsible. But a more fundamental problem is the dysfunctional nature of distribution companies (DISCOMS)—inefficiently run with huge losses, they don’t have the money to buy power and supply it to people. Meanwhile, huge generating capacity lies idle. This also exacerbates pollution problem—DISCOMS prefer buying from the older, more polluting power plants because their electricity is cheaper than that generated by the new plants. This happens because the old plants are fully depreciated and, as a result, their input cost is lower.

Road map for old plants: While the introduction of standards for new plants is a welcome move, more work is needed to address impacts of the existing old power plants. Old plants accounted for the bulk of the environmental impacts in the CSE study. Without stricter requirements on old plants, there will be little incentive to invest in improved technologies. In a recent departure from its policy to retire relatively small capacity (around 4 GW of capacity in the 13th Five Year Plan period), the government announced it plans to retire 36 GW of old coal-fired units. The new announcement if implemented should lead to improvements in overall efficiency.

Enforcing ambitious timelines: Power sector has in the past failed well short of its ambitious targets. In the last several plan periods, coal-based power capacity expansion was well below the targets. In the 12th Five Year Plan (2012-17), for example, only 2.7 GW of old plants have so far been refurbished as opposed to the target of 29 GW.

The new norms would require installing cooling towers at numerous plants; SO2 control would require installing flue-gas desulfurizations within two years. Regulators would need to establish clear milestones and ensure close supervision to ensure implementation of these rules.

Emissions data monitoring: One of the key findings of CSE’s study was the widespread under reporting of emissions. Most plants reported compliance to air pollution norms on paper while flagrantly flouting pollution norms. With further tightening of norms, it is critical that the framework for monitoring and reporting of pollution data also be overhauled.

While the continuous monitoring of ambient air quality data has become common, monitoring of stack emissions (include NOx, N2O, CO, CO2, O2, SO2 and CxHy emissions) remains a manual practice. Continuous emissions monitoring system (CEMS) can be instrumental in improving governance of pollution performance. The US and Europe have been extensively using CEMS for monitoring stack emissions while China has adopted the technology for SO2 monitoring and trading. In India, however, CEMS is at a nascent stage. In April 2015, Ministry of Environment, Forest and Climate Change (MOEF&CC) issued a draft notification for installation of cems and its monitoring and reporting protocol, but detailed framework and guidelines are yet to be established. Like in manual reporting CEMS is also afflicted with problems of data manipulation and would need robust protocols and standards to ensure the sanctity of data.

Fly ash and market economics: The proposed notification on fly ash use is a step forward, but gaps remain that will continue to inhibit use. Currently cement sector is the dominant user of fly ash (see ‘Industry break-up of fly ash utilisation’, p99). While the norms will improve the supply of fly ash to end-users it is not doing enough to create demand for fly ash products like bricks or push road making. Policies of different government departments, regulators and construction agencies on the use of fly ash for construction are not consistent. For instance, building bye laws of municipalities, which set rules on use of construction material, don’t compulsorily require use of fly ash bricks for construction.

Overall, the proposed and new regulations are an important first step. Coal-based power is artificially cheap because of two reasons—coal for generating power is subsidised and the health and environment costs of coal are not incorporated. The new regulations would result in a small step to add some of the costs by pushing investment in pollution control technology. It will also have the added benefit of somewhat leveling the playing field for renewables and making them competitive sooner. Given that fly ash generation is going to increase rapidly in the future, it is imperative that its productive use is successfully popularised (see ‘Fly ash generation by coal-based power sector and percentage utilisation’, p99)

We are a voice to you; you have been a support to us. Together we build journalism that is independent, credible and fearless. You can further help us by making a donation. This will mean a lot for our ability to bring you news, perspectives and analysis from the ground so that we can make change together.

India Environment Portal Resources :

Comments are moderated and will be published only after the site moderator’s approval. Please use a genuine email ID and provide your name. Selected comments may also be used in the ‘Letters’ section of the Down To Earth print edition.