Though the cognisance of the offence is a welcome move, the court could have widened its scope to benefit many

The jury is still out on whether the National Green Tribunal (NGT)’s decision to levy a penalty of Rs 50 crore on LG Polymers India will set a precedent to prevent future disasters.

The principal bench of the NGT took a suo-moto hearing on the gas leak incident in Visakhapatnam, Andhra Pradesh on May 8, 2020, that led to the deaths of 11 persons and hospitalisation of hundreds.

Justice Adarsh Goel and the bench ordered LG Polymers India Pvt Ltd to deposit Rs 50 crore towards the damages caused to the environment and life prime-facie to the district magistrate.

The NGT issued orders under Sections 14 and 15 of the NGT Act, 2010. The bench also issued notices to Andhra Pradesh State Pollution Control Board (SPCB), district magistrate of Vishakhapatnam, Central Pollution Control Board, Union Ministry of Environment, Forests & Climate Change (MoEF&CC) and LG Polymers India Pvt Ltd to respond.

The court also appointed a five-member committee of experts to report its initial findings on the causes of failure, extent of damage and remedial measures initiated in another 10 days.

However, the court did not make any mention of the two other industrial accidents that also happened along with Visakhapatnam on May 7.

Gas leaked at a paper mill in Raigarh, Chhattisgarh, affecting workers who were housekeeping at the units. The third incident was at the Neyveli thermal power station in Tamil Nadu. Two boilers of 210-megawatt capacity blasted, injuring about 10 people.

The common thread running among these incidents was the poor operational and maintenance practices during the lockdown, besides shortage of skilled staff for maintenance work.

“Maintaining power stations or any industries with less staff is a risk and such incidents in this scenario are not surprising,” according to industry experts.

Though the cognisance of the offence is a welcome move, the court could have widened its scope to benefit many.

It could have directed the government to circulate an immediate directive to industries that all industrial units should ensure safety while resuming operations -- in case the lockdown continues, these safety precautions must not be negated.

The Court also did not clarify if the district magistrate can use the funds to initiate relief measures.

Violations in environmental clearances

Industries processing petrochemical-based products require two levels of clearances to function – one from the MoEF&CC and the other from the SPCB.

The clearance obtained from the MoEF&CC is called the ‘Environmental Clearance’ and that from the SPCB is the ‘Consent to Operate’ that needs to be renewed periodically in a span of five years.

An old company like LG Polymers India Pvt Ltd that has been operating even before the legislation of Environmental Impact Assessment would have to obtain the Environmental Clearance if it plans to expand its production, change raw material or modernise its units.

The firm has been producing different facts before various authorities to obtain consent from the states and has successfully brushed aside the need to carry out any impact and risk assessment studies. This negligence could also have been a potential reason for the disaster.

Timeline

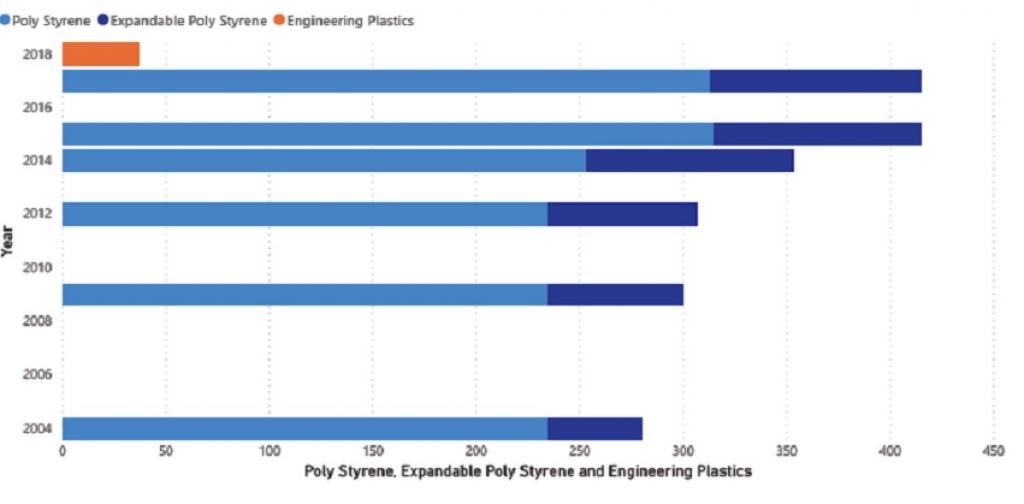

Year-wise consent given by SPCB on products which can be manufactured (capacity in tonnes per day)

“The plant, by failing to seek Environmental Clearance, has violated informing the competent authorities over two things: One is changing product mix and related impacts. The second is the expansion and importing,” DD Basu, advisor, Centre for Science and Environment, said.

“Expansion means more storage. Importing means risk associated with transportation, handling in port related goods for loading and unloading the same in factory premises. In fact, the plant needs to apply afresh. Renewal of Consent to Operate is not the only issue. Since it has changed the product mix and production process, the risk associated with accidental release is more,” he added.

We are a voice to you; you have been a support to us. Together we build journalism that is independent, credible and fearless. You can further help us by making a donation. This will mean a lot for our ability to bring you news, perspectives and analysis from the ground so that we can make change together.

India Environment Portal Resources :

Comments are moderated and will be published only after the site moderator’s approval. Please use a genuine email ID and provide your name. Selected comments may also be used in the ‘Letters’ section of the Down To Earth print edition.